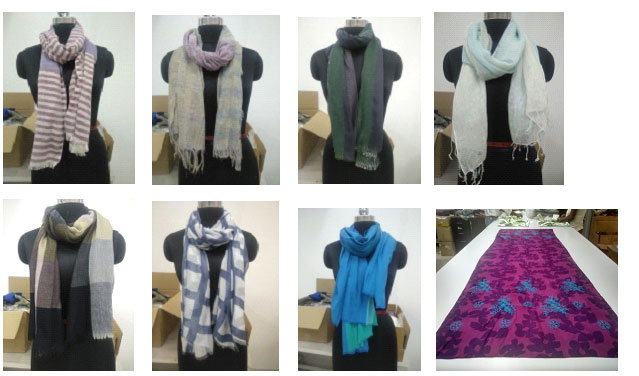

Inspection of Woven Scarf

Email: info@inspection-india.com

A scarf, plural scarves, is a piece of fabric worn around the neck for warmth, sun protection, cleanliness, fashion, or religious reasons. They can be made in a variety of different materials such as wool, linen or cotton. It is a common type of neckwear.

Types of Scarves

# Cashmere. # Alpaca. # Silk. # Cotton. # Linen. # Pashmina. # Fleece. # Wool.

# From the fleece of the sheep and a range of other animals, wool comes in a variety of textures and styles depending on how its woven, but is traditionally very warm and durable.

Inspection of Scarf

The scarf is very soft and warm of product. They are easily fit on person and there are different type materials used in product scarf just like – Cotton, Silk, Linen, Viscose and Modal etc.

There are different types of work on product Scarf like – Embroidery, Hand Embroidery, Printed Scarf, Woven Scarf, Pom-pom and Tassel attaching at scarf, Computer Embroidery, Laser Printing Etc.

Printed & computer embroidery Viscose Scarf

Laser Printed Viscose Scarf

- When we start inspection, checking as per Client’s PO and packing list provided by Supplier’s during the inspection. The Inspector has checking quantity as per PO. Client then offering qty selected boxes and as per AQL Standard.

- We will check spec sheet, Material test, shade matching, Measurement, Testing Report, Shipment sample approval, P. P. Sample approval, wash care label standard, packing and marking doing inspection.

- Workmanship as per AQL Standard to be checked.

- Shade matching as per Client’s Requirement TL-84, U-3500 & D-65

- As per Tolerance of Measurement and weight of pcs to be checked

Scarf Width & Length – Width should be from 6 to 14 inches, length from 50 to 90 inches, although an average height man wants a scarf at least 60 inches and a larger man should look for one in the 70 inch range.

Traditionally, a scarf goes tip to tip. To do this, try holding your arms out so that the scarf reaches from your left finger across to your right one. On average, this scarf will be about 60″ long. Most short scarves are 55″ long, medium scarves are roughly 70″ extended, and long scarves are about 82″ in length.

There are lots of different ways for men to wear keep their necks warm and look stylish. Putting on an infinity scarf is not one of them. … Most scarves end up getting wrapped around the neck in a cylinder anyway, so the infinity scarf simply realizes a sartorial inevitability.

Shade matching pcs to pcs as per Standard

55% cotton 45% Modal-Printed Scarf

The scarves come in various shapes, sizes and most essentially in various fabrics. … Scarf Universe provides scarves in various materials that are 100% pure and genuine. We offer scarves of materials like pure silk, cashmere, wool, cotton, viscose, linen, polyester and many more.

In cold climates, a thick knitted scarf, often of wool, is tied around the neck to keep warm. This is usually accompanied by a warm hat and heavy coat. … The most popular are ladies’ silk scarves, cotton scarves and linen scarves.

Computer Embroidery Linen Scarf

Computer Embroidery Linen Scarf

There are three type defects Critical Defect, Major Defects and Minor Defects

Critical Defects

- Any metal contamination in a product including

Pins, needles, staples, tag gun needles.

- Any potentially dangerous components.

- Infestation within product, packaging or cartons or evident infestation.

- Missing legal requirements.

- Missing or incorrect labelling (components or percentage.

Major Defects

- Incorrect barcode

- Measurements out of specification (specify)

- Miscellaneous items out of specification (specify)

- Visible fabric defects that are likely to deter customer purchasing product

- Visible sewing defects that are likely to deter a customer from purchasing product

- Visible processing defects (dyeing, printing shearing, finishing etc.

- Bow or skew (usually 3% on total width or 1” or2.5cms on prints. (Off grain)

- Damage to product (soiling, stains, holes, cuts, tears etc – specify

- Roping at hems or seams

- Missing, damaged or poorly fitting components and accessories

- Incorrect fabric/material not matching the approved reference sample

- Open seams or holes greater than 10mm

- Raw, unbound or frayed fabric edges

- Grinning seams

- Sewing thread poor colour match/incompatible with base fabric

- Incorrect colour match with the approved reference sample or inconsistent colouring of co-ordinating products

- Missing, damaged, misleading, illegible or incorrect details on packaging, labels, instructions, warnings etc Missing, damaged, misleading, illegible or incorrect, details

- Dampness, odour of mould

- Broken zips

- Insecure buttonhole or cut stitches at buttonhole

Minor Defects

- Inconspicuous fabric defects (pulled threads, neps, slubs, knots, irregular yarn- thick/thin places – specify that is likely to deter customer from purchasing article

- Sewing defects ( stitch pucker, mis-position label, thread ends etc that is likely to deter customer

- Thread ends over 2cm

- Roping at hems or seams

- Dirt, staining or soiling- inconspicuous small areas only

- Open seams or holes less that 10mm